TPF – Hi-Lo Pumps

[!–VMCatalog{div class=”product-image float-left” style=”width:30%; margin-top:140px; margin-left:50px;”}–]

[!–VMCatalog{/div}–]

[!–VMCatalog{div class=”ordering-code” style=”width:45%;”}–]

Ordering Code

| TPF | -VL30 | 2 | -GH | 2 | -11 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Series No. | Shaft end Pump | Variable Volume pressure compensated vane pump | Cover end Pump | Fixed Displacement Gear Pump | Design No. | ||||

| Outlet Flow (lpm) at 3.5 bar, 1800 rpm | Operating Pressure range (bar) | Displacement (lpm) | Operating Pressure (bar) | ||||||

| TPF

Flange Mounting |

Code | Outlet Flow (lpm) | Code | Pressure Range | Code | Outlet Flow | Pressure | Peak | 11: PT(Rc) |

| VL30 | 30 lpm | 1 | 15 ~ 35 bar | GH1 | 1.09 | 210 | 250 | ||

| VL40 | 40 lpm | 2 | 30 ~ 70 bar | GH2 | 2.07 | ||||

| Factory Setting Qmax. | Factory Setting Pmin. | GH3 | 3.08 | ||||||

| GH4 | 4.06 | 1180: PF(G) | |||||||

| GH5 | 6.16 | ||||||||

| GH6 | 7.67 | ||||||||

| GH7 | 9.24 | ||||||||

| GH8 | 10.77 | 1190: NPT | |||||||

| GH9 | 12.0 | ||||||||

| G00 | G00 type is variable vane pump only. It does not include the gear pump | ||||||||

[!–VMCatalog{/div}–]

[!–VMCatalog{div class=”clear-fix”}/–]

[!–VMCatalog{div id=”product-tabs”}–]

[!–VMCatalog{div id=”tab-1″}–]

Operating Data

[!–VMCatalog{div style=”margin-top: 10px;margin-bottom: 20px;”}–]

ROTARY DIRECTION

Clockwise rotation viewed from shaft end is standard.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

FLUIDS PERMISSIBLE

When working pressure lower than 70 bar, hydraulic oil with a viscosity ranging from 30~50 cSt(ISO VG32). When working pressure higher than 71 bar .hydraulic oil with a viscosity ranging from 50-70 cSt(ISO VG68) at 40°C is recommended.(ISO VG32) at 40 °C is recommended.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

DRAIN PORT PIPING

Drain connection must be piped directly to tank and below the oil level with a back pressure not exceed 0.3 bar.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

OIL TEMPERATURE RANGE

Oil temperature range should be between 15-60°C for continuous operation and should be higher than 7°C at starting.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

ALIGNMENT AND INSTALLATION OF PUMP

The shaft alignment for pump and electric motor shall be limited to 0.05mm TIR. and 1 degree angular error.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

INLET PORT PRESSURE

Inlet port pressure should be -0.3 bar to +0.3 bar.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

FLOW ADJUSTMENT

The flow will be reduced when the flow adjusting screw is turned clockwise and increased when anti-clockwise.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

PRESSURE ADJUSTMENT

The pressure will be increased when the pressure adjusting screw is turned clockwise and reduced when anti-clockwise.

P-Q CHARACTERISTICS ( EX-WORK SET ) Flow setting:The max. flow as catalogue shown. Pressure setting:The min. operating pressure range.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

SLIDE SCREW

The slide screw is non-adjustable and set at factory. Unauthorized persons cannot tamper with the desired setting.

[!–VMCatalog{/div}–]

[!–VMCatalog{div style=”margin-bottom: 20px;”}–]

CAUTIONS FOR STARTING

Start up the pump under No-Load condition and repeat to start and stop the motor several times to extract the air from inside of the pump and piping.Then keep a 10 minutes continuous running for a better de-airing.

[!–VMCatalog{/div}–]

[!–VMCatalog{div}–]

PEAK-PRESSURE

The peak pressure is 140 bar for code * 2 & * 3,and 210 bar for A4 & A5.

[!–VMCatalog{/div}–]

[!–VMCatalog{/div}–]

[!–VMCatalog{div id=”tab-4″}–]

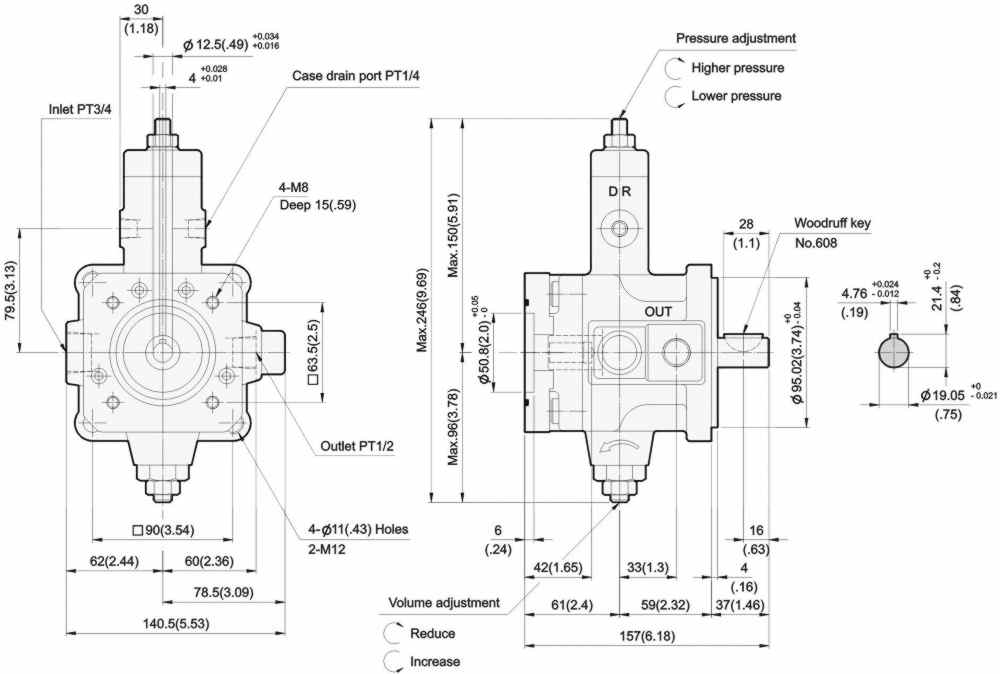

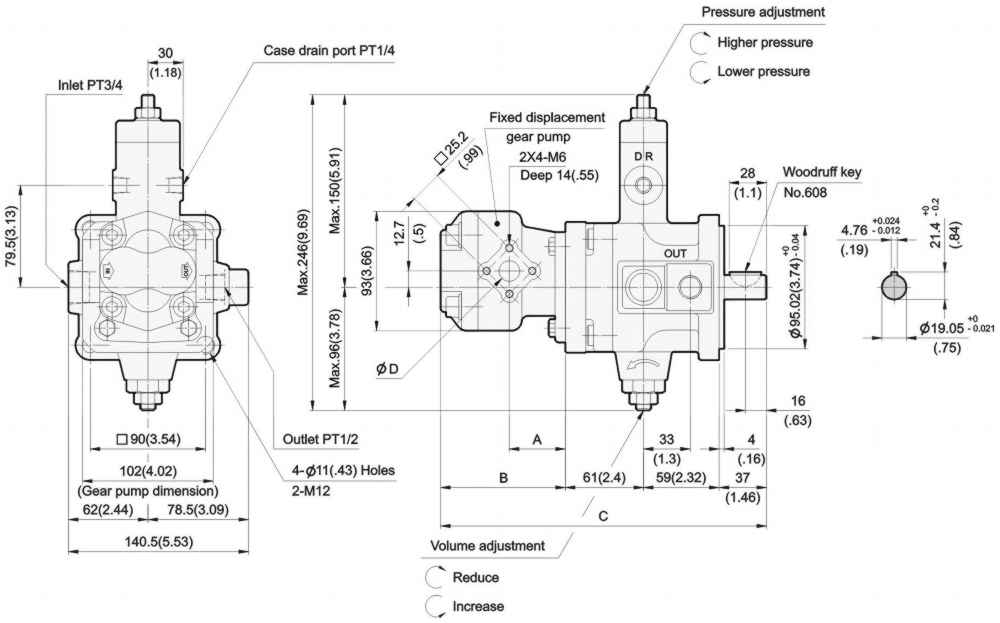

Dimensions

TPF-VL***-G00-11 Dimensions

TPF-VL***-GH-11 Dimensions

[!–VMCatalog{/div}–]

[!–VMCatalog{/div}–]